The Engineering and Advantages of LVT Flooring

When selecting the ideal flooring, consumers have a plethora of choices, but few match the versatility and resilience of Luxury Vinyl Tile (LVT). To comprehend why LVT has become such a popular choice for both residential and commercial applications, it’s essential to delve into its composition, the technology behind its manufacture, and the benefits it offers over traditional materials.

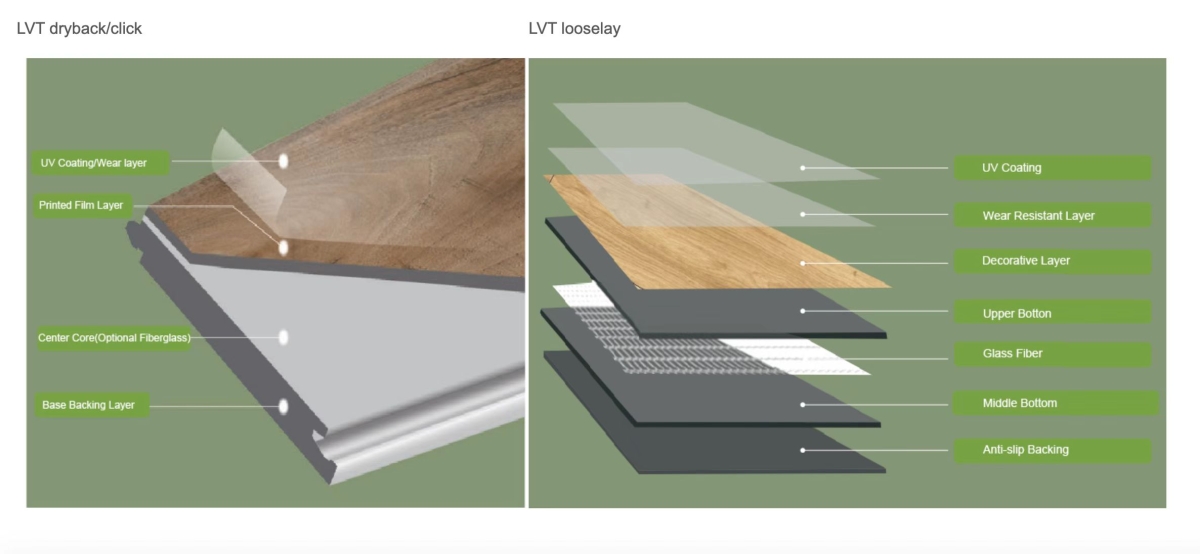

The Multilayer Structure of LVT

The superior performance of LVT flooring is largely due to its sophisticated multilayer structure, which includes

UV Coating & Wear Layer: The top layer of LVT is coated with UV-cured urethane, creating a barrier that resists scratches and scuffs, thereby extending the life of the flooring. It protects against daily wear and tear while making the floor easier to clean and maintain. This coating can also be enhanced with anti-microbial properties to improve hygiene.

Print Film Layer: This is where high-fidelity printing technology is utilized to accurately reproduce the visuals of natural materials like hardwood, stone, or ceramic tiles. The level of detail in this layer is paramount, as it dictates the overall aesthetic quality of the flooring.

Vinyl Core Layer: The core layer generally consists of PVC (polyvinyl chloride) and may include additional compounds to enhance rigidity and stability, such as SPC cores infused with natural limestone powder. This layer provides the flexibility and strength characteristic of LVT, ensuring the flooring can withstand heavy foot traffic and the stress of everyday use.

Backing System: The backing material might incorporate foam or cork, offering not only another moisture barrier but also adding acoustical dampening and softness underfoot, improving the comfort and quietness of walking on the floors.